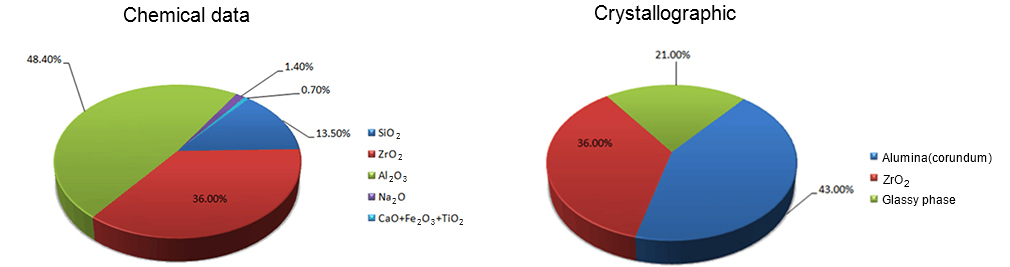

Fused cast AZS-36 can provide improved service over AZS-33, which is an type of AZS fused cast refractory produced by YUANDONG having 36% ZrO₂ content.

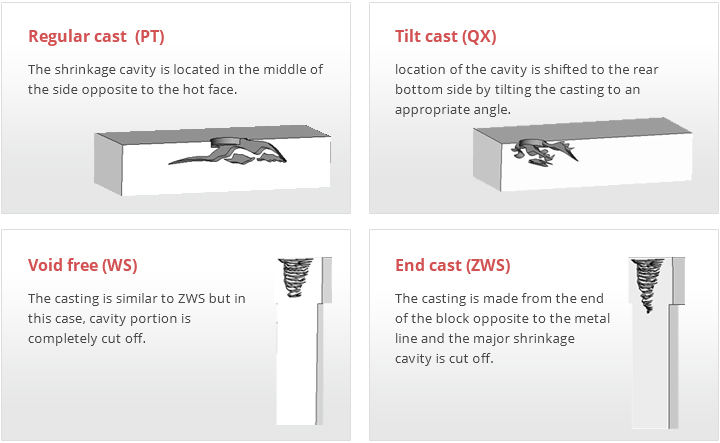

When developing the production technology of fused cast AZS, YUANDONG has always taken great care to eliminate or control the dispersion of shrinkage cavities during solidification of the fused material, as this has a great influence on the behavior and resistance of the blocks against wear in operation. YUANDONG manufactures AZS-36 blocks by different casting methods.

| Type | Casting method | description | Bulk density Kg/dm³ | application |

|---|---|---|---|---|

| PT | Regular cast | The shrinkage cavity is located in the middle of the side opposite to the hot face. | ≥3.50 |

•superstructures •working ends •feeder channels •not glass contact areas |

| QX | Tilt cast | location of the cavity is shifted to the rear bottom side by tilting the casting to an appropriate angle | ≥3.50 | •sidewalls |

| ZWS | End cast | The casting is made from the end of the block opposite to the metal line and the major shrinkage cavity is cut off. | ≥3.70 | •sidewalls |

| WS | Void free | The casting is similar to ZWS but in this case, cavity portion is completely cut off. | ≥3.80 |

•sidewalls •paving •special shapes |

| E-mail : lsyd@lsyd.com | |

| 0086-371-69275999 0086-371-69276100 | |

| Wulibao Industrial Zone, Dawei,XInmi,Henan,China |